Our machine park

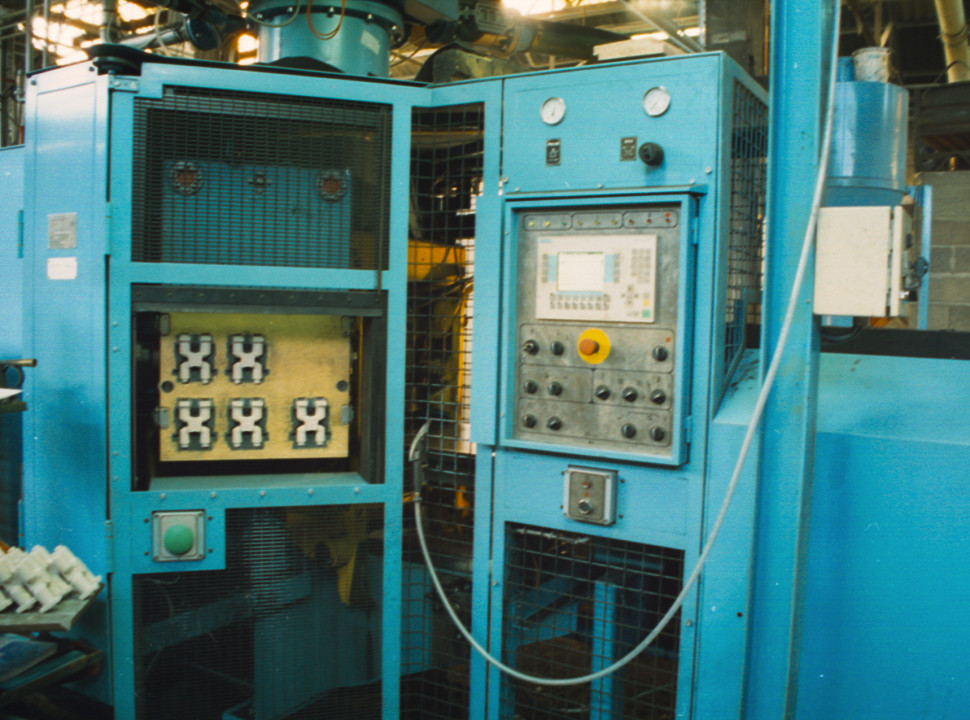

- Coring with 2 processes ISOSET and CRONING

- Electric induction melting furnaces with a capacity of 1.2 tons/h and 1.6 tons/h

- DISAMATIC sand molding line with a holding/casting furnace with automatic ladle, inverter-controlled and infrared temperature probe

- Pepset hand molding workshop for single parts or small series and special alloys with induction push-out fusion in a 140 Kg crucible

- Automated shot blaster

- Grinding and trimming press workshop

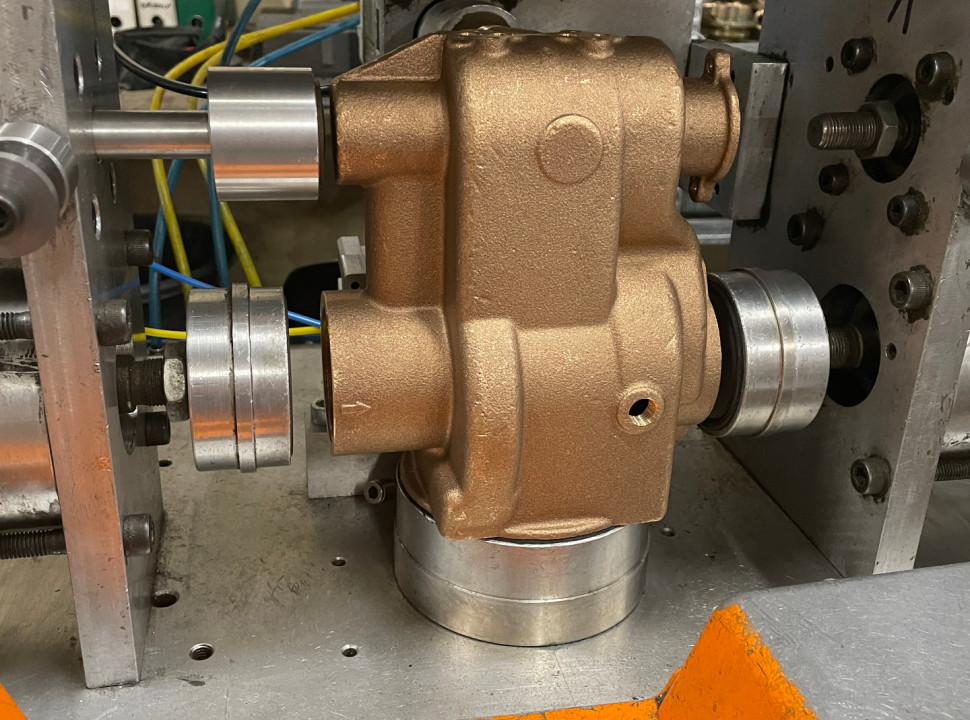

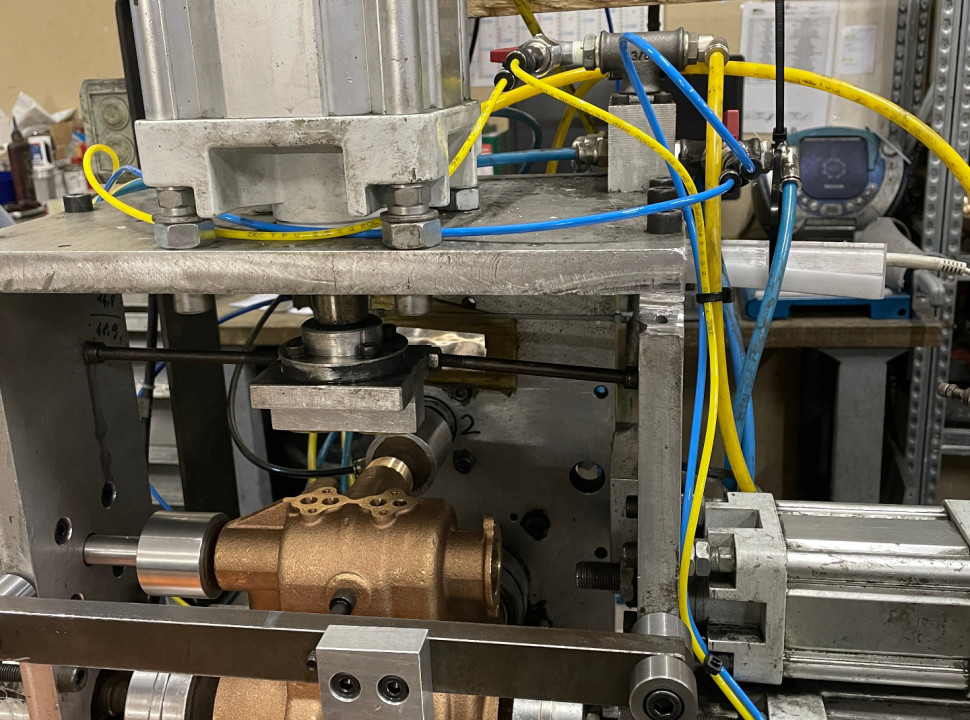

- Robotized deburring and pressing cell to ensure high-quality finishes

All these material and software resources would be useless without a competent and experienced team (foundry engineer, quality specialist, toolmaker, modeler, team leader, core maker, molder, hand molder, founder, discharger, shot blaster, deburrer, controller, test operator, HSE manager, forklift driver…)