Our specialty lies in the casting of copper alloy and bronze parts using sand casting, allowing us to meet our clients' needs with precision, regardless of the project size: whether it is a prototype, small, medium, or large series.

Production capabilities tailored to your specific needs

Fonderie Boisson has the production capabilities and human skills for production tailored to each specific need.

Manufacturing process

-

Melting

Our melting process relies on modern, environmentally friendly means: induction electric furnaces, including 2 melting furnaces with a capacity of 1.2 tons and 1.6 tons, and an automatic pouring furnace of 2 tons, ensuring a continuous supply to the molding chain and a pouring temperature within +/- 5 degrees. -

Sand casting

We are leaders in our market thanks to our innovative Disamatic vertical molding technology, combined with automated metal pouring, tailored for series production, ensuring high-quality parts within competitive lead times. Thanks to our hand-molding process with chemical grip, we are also able to produce prototypes or small batch parts. -

Control

We implement several controls to ensure the quality of our products: alloy control at each pour using the spectrometer, regular analysis of the molding sand by our laboratory, verification of the material quality of each series of cast parts through destructive testing, and individual inspection of each part produced before shipment.

The copper alloys used by Fonderie Boisson

Each material has unique characteristics and specific advantages, perfectly suited to various applications. With this in mind, we have developed a summary table of the main materials we use in our manufacturing process, and we are at your disposal to advise you.

| Eléments + Symbole |

CuSn5Zn5Pb2 (CB499K) UBA |

CuSn5Zn5Pb5 (CB491K) |

CuSn10 (CB480K) |

CuSn11Pb2 (CB482K) |

CuSn12 (CB483K) |

CuZn25Al5Mn4Fe3 (CB762S) |

CuZn39Pb1Al (CB754S) |

CUPRO- |

Bronze au Bismuth (C89833) |

CuSn4Zn2PS Lead free |

|---|---|---|---|---|---|---|---|---|---|---|

| Cuivre / Copper / Cu | 84 % – 88 % | 83 % – 87 % | 88 % –90 % | 83,5 % – 87 % | 85 % – 88,5 % | 60 % – 66 % | 58 % – 62 % | >78 % | 86 % – 91 % | 90,0 % - 96,0 % |

| Etain / Tin / Sn | 4 % – 6 % | 4 % – 6 % | 9 % – 11 % | 10.5% –12,5% | 11 % – 13 % | 0,2 maxi | 1 % maxi | - | 4 % – 6 % | 3 % – 5 % |

| Plomb / Lead / Pb | 0.2% - 3 % | 4 % – 6 % | 1.0 % maxi | 0,7 % – 2,5 % | 0,7 % maxi | 0,2 maxi | 0,5 % – 2,4 % | - | 0.09% maxi | 0.2% maxi |

| Zinc / Zn | 4 % – 6 % | 4 % – 6 % | 0,5 % maxi | 2 % maxi | 0,5 % maxi | reste | reste | - | 2 % – 6 % | 1 % – 3 % |

| Fer / Iron / Fe | 0,3 % maxi | 0,3 % maxi | 0,2 % maxi | 0,2 % maxi | 0,2 % maxi | 1,5 % – 3,5 % | 0,7 % maxi | 3 % - 5 % | 0.3% maxi | 0,3% maxi |

| Nickel / Ni | 0,1% - 0.6% | 2 % maxi | 2 % maxi | 2 % maxi | 2 % maxi | 2,7 maxi | 1 % maxi | 3 % – 5 % | 1% maxi | 0,3% maxi |

| Soufre / Sulphur / S | 0,04 % maxi | 0,1 % maxi | 0,05 % maxi | 0,08 % maxi | 0,05 % maxi | - | - | - | 0.08% maxi | 0,2% - 0,6% |

| Phosphore / Phosphorus /P | 0,04 % maxi | 0,10 % maxi | 0,2 % maxi | 0,4 % maxi | 0,6 % maxi | 0,02 maxi | 0,02 % maxi | - | 0.05% maxi | 0,01% - 0,1% |

| Aluminium / Ai | 0.02 % maxi | 0,01 % maxi | 0,01 % maxi | 0,01 % maxi | 0,01 % maxi | 4 % – 7 % | 0,1 % – 0,8 % | 10 % – 11,5 % | 0.005% maxi | 0,02 % maxi |

| Silicium / Si | 0.02 % maxi | 0,01 % maxi | 0,02 % maxi | 0,01 % maxi | 0,01 % maxi | 0,08 maxi | 0,05 % maxi | - | 0.005% maxi | 0,02 % maxi |

| Bismuth / Bi | - | - | - | - | - | - | - | - | 1.7% - 2.7% | - |

| Antimoine / Antimony / Sb | 0,1 % maxi | 0,25 % maxi | 0,2 % maxi | 0,2 % maxi | 0,15 % maxi | 0,03 maxi | - | - | 0,25% maxi | 0,1% maxi |

| Arsenic / As | - | - | - | - | - | - | - | - | - | - |

| Manganese / Mn | - | - | 0,1 maxi | 0,2 maxi | 0,2 % maxi | 3% – 5 % | 0,5 % maxi | 3,5 maxi | - | - |

The foundry method

Fonderie Boisson has developed a meticulously designed working method at each step to ensure quality, precision, and total customer satisfaction.

Detailed quote

We start by preparing a detailed quote, taking into account the customer’s specifications and requirements.

- Plan review

Once the quote is accepted, we proceed with a detailed review of the plans to ensure a clear and precise understanding of the customer's needs. - Tooling creation

Next, we begin the creation of the necessary tooling, including the core box, model plate, press tooling, machining tooling, and sealing test tooling. Each step is validated in 3D by the client to ensure perfect alignment with their expectations. - Prototype part creation

Once the tooling is validated, we proceed with the creation of prototype parts to confirm compliance with specifications and for initial testing. - PPAP Qualification

We are committed to meeting the highest quality standards by performing a PPAP (Production Part Approval Process) qualification, thus ensuring complete compliance of our parts with the customer's requirements. - Series production

Finally, once all steps are validated, we launch serial production while maintaining constant monitoring to ensure consistent quality throughout the process.

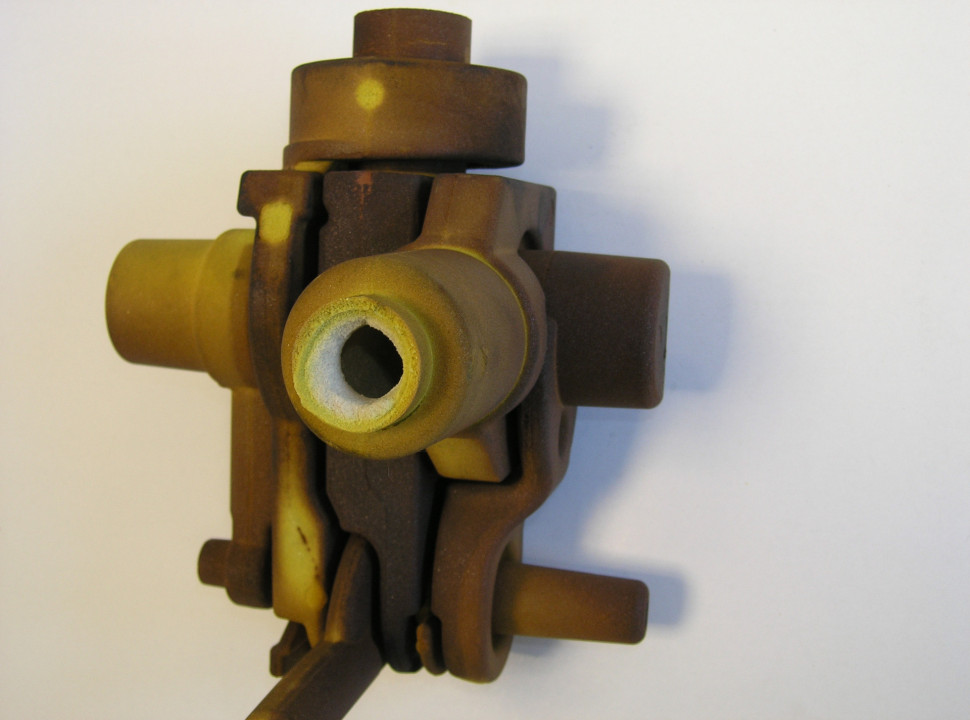

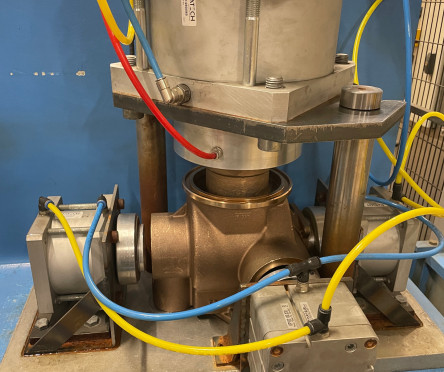

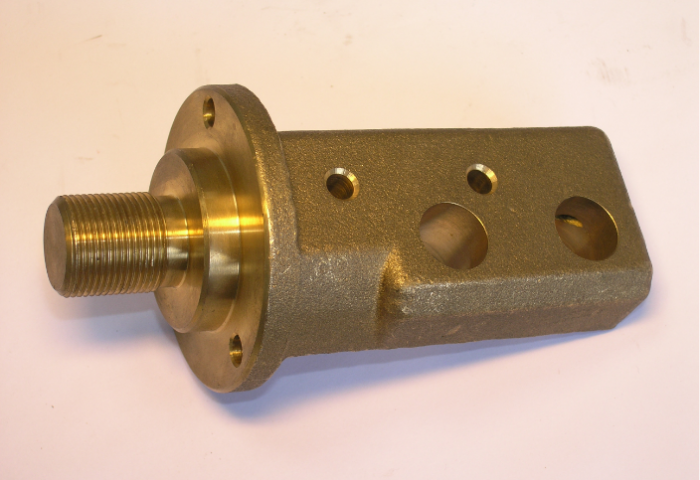

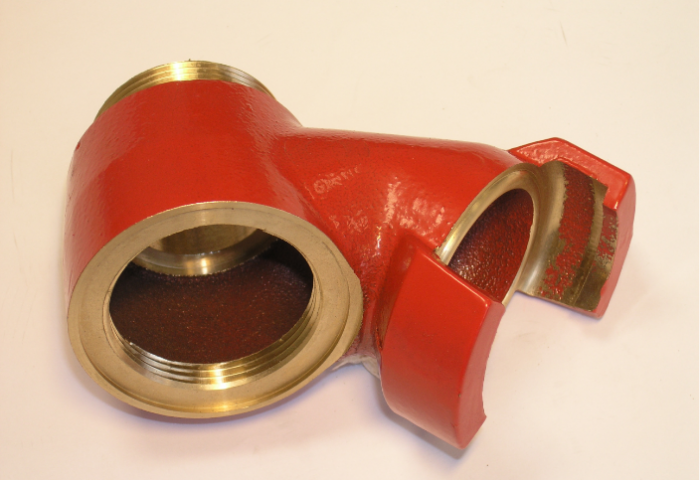

Some examples of parts made by Fonderie Boisson

-

Electricity

Electric spindle -

Water treatment

Water treatment -

Fire

Fire intake