In-house manufacturing of tools and molds: Quality and flexibility guarantee

At the heart of our manufacturing process lies our ability to produce our own tools in-house.

This vertical integration gives us complete control over the quality, precision, and production times of our parts.

It allows us to optimize the efficiency of our manufacturing process while ensuring great flexibility to meet the specific needs of our customers.

An integrated design office

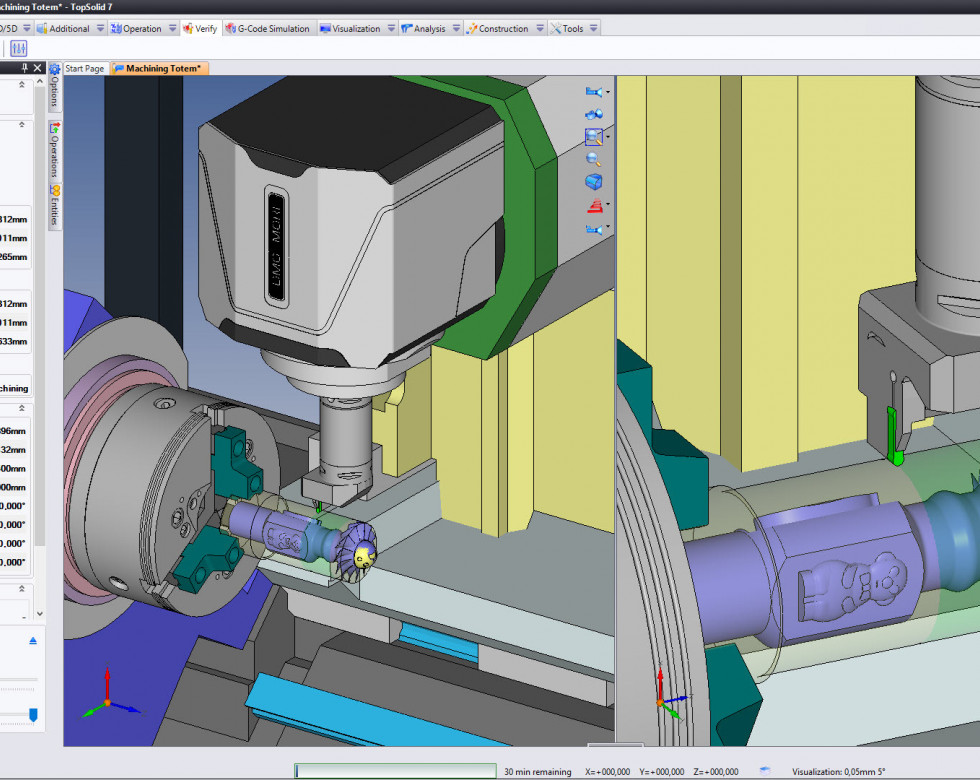

Our integrated design office is a central pillar of our manufacturing approach. Equipped with the most advanced technologies such as CAD, CAE, and CAM, we are able to design and model every aspect of our products with great precision.

From the design phase, we can anticipate and solve potential problems, thus ensuring optimal quality of our finished parts by meeting the most complex requirements thanks to our expertise with the Novacast casting simulation software.

We can also offer functional prototyping using 3D-printed sand molds (without tooling).

Our production capabilities:

Our core principles:

- Environmental responsibility

- Recycling of materials (chips, old parts, etc.)

- Commitment to human well-being

- Continuous quality improvement

- Listening to and advising our customers